|

|

Build Your Online Product Catalogs?

| Product Name: |

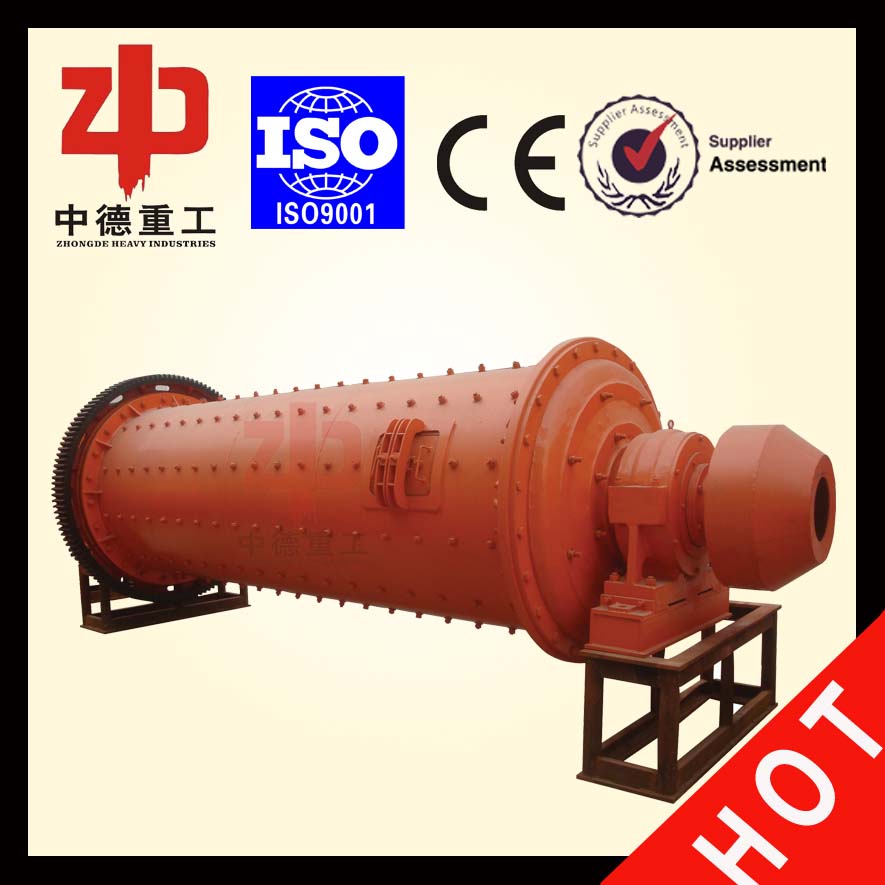

high quality and energy-saving MQY-2736 type overflow ball mill

|

| Supply Ability: |

|

| Related proudcts |

ball mill, ball miller, |

| Specifications |

MQY-2736 |

| Price Term: |

FOB |

| Port of loading: |

tianjin,qingdao port etc |

| Minimum Order |

1 |

| Unit Price: |

138710 USD |

|

Application:

Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

It also can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Types:

Mill could be sorted as following:

As per the grinding media: ball mill, rod mill and AG Mill (without grinding media).

As per material discharging mode: wet grid mill, dry grid mill & overflow mill.

As per driving mode: side & central driving. The former is more popular now.

As per driving configuration:

a. Asynchronous motor driving: Asynchronous motor + Reducer + Pinion +Girth gear

b. Synchronous motor driving: Synchronous motor+ Air clutch+ Pinion +Girth gear

c. Asynchronous motor + reducer + diaphragm coupling

Structure of Ball mill:

The machine is composed of feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control).

The quill shaft adopts cast steel part and the liner is ***achable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance.

Working principle:

The ball mill is horizontal cylindrical rotation device, driven by brim gearwheel.

There are two chambers and grid. Material goes into the first chamber through the feeding inlet. Inside the first chamber, there are stage liners and ripple liners as well as steel balls. The shell rotates so as to generate electricity, and this force brings ball to a certain height and then balls drop down by gravity, the i***ct is the grinding force to the material.

After the primary grinding, materials go into the second chamber through segregate screen. In the second chamber, there are flat liners and steel ball. After the secondary grinding, material is discharged from the discharging mouth. Then the whole grinding pro |

| Company: |

Zhongde Heavy Industry Co,ltd

|

| Contact: |

Ms. tina chen |

| Address: |

Industrial Park, Luoyang city |

| Postcode: |

471822 |

| Tel: |

86-0379-67308060 |

| Fax: |

86-0379-67312018 |

| E-mail: |

|

|

|

|